产品概述

HB系列是我公司自行研制的不锈钢耐腐蚀离心泵该系列泵的的叶轮可采用半开式结构,也可采用闭式结构,另外,泵与电机的联接方式又有直联式和带轴承托架式两种,泵的轴封均采用目前西德较先进的悬臂式技术的机械密封,过流零部件及连接架采用优质不锈钢材料制造。所以,HB不锈钢耐腐蚀泵系列产品具有耐腐蚀性能可靠,使用、维护方便、结构紧凑、能耗低、密封性能好等一系列优点。

主要用途

HB系列泵可输送温度不高于120℃(直联式)或不高于150℃(带轴承托架式),含(或不含)有细小软颗粒或纤维质,带腐蚀性或有卫生要求的液体,广泛适用于食品、饮料、医药、污水处理、化工、电镀、漂染、精细化工等行业使用。

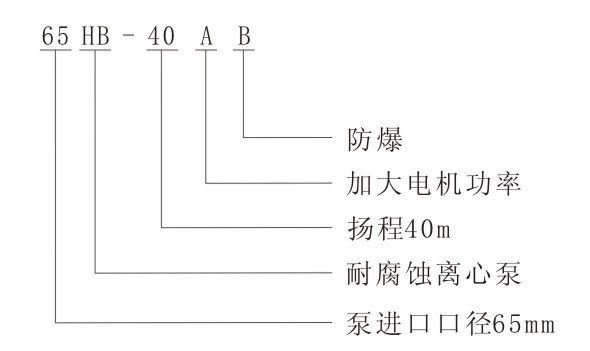

型号意义

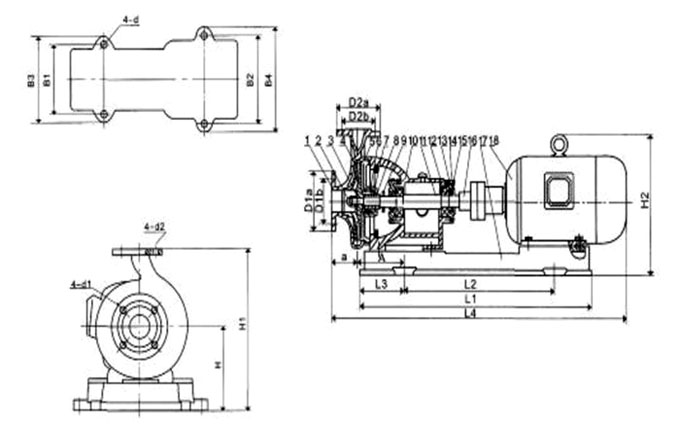

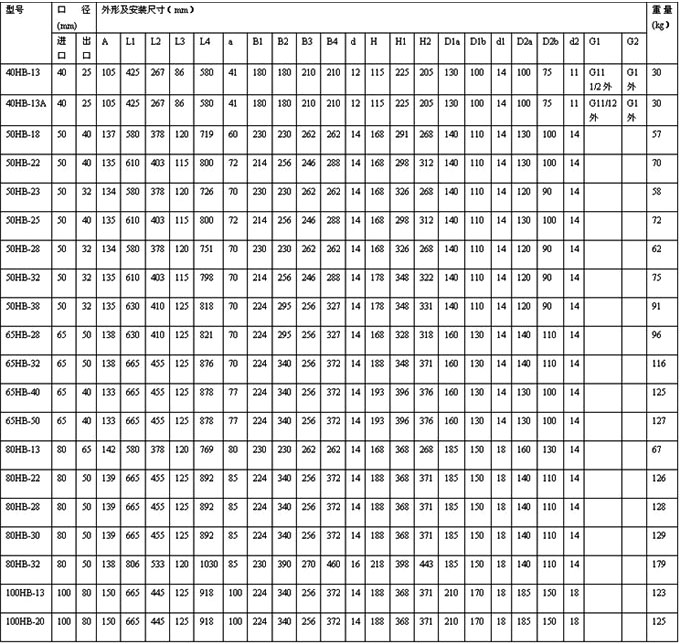

安装尺寸

性能参数

| 型号 |

口径(mm) |

扬程H(m) |

气蚀余量(m) |

电机功率(kw) |

转速(r/min) |

电压(v) |

| 进口 |

出口 |

流量Q(m?/h) |

| 40HB-13 |

40 |

25 |

H |

16 |

15 |

14 |

13 |

11 |

8 |

6 |

3.5 |

0.55 |

2800 |

380 |

| Q |

25 |

4.5 |

5.3 |

6 |

8.3 |

10.8 |

12 |

| 40HB-13A |

40 |

25 |

H |

16 |

15 |

14 |

13 |

11 |

8 |

6 |

3.5 |

0.75 |

2800 |

380 |

| Q |

25 |

4.5 |

5.3 |

6 |

8.3 |

10.8 |

12 |

| 50HB-18 |

50 |

40 |

H |

23 |

22 |

20 |

18 |

16 |

15 |

14 |

3.5 |

1.5 |

2800 |

380 |

| Q |

15 |

4.3 |

9 |

13 |

15.5 |

16.5 |

17.6 |

| 50HB-22 |

50 |

40 |

H |

27 |

26 |

24 |

22 |

20 |

19 |

18 |

3.5 |

2.2 |

2800 |

380 |

| Q |

7 |

10 |

16 |

19 |

22 |

23 |

24 |

| 50HB-23 |

50 |

32 |

H |

26 |

25 |

24 |

23 |

20 |

17 |

14 |

3.5 |

1.5 |

2800 |

380 |

| Q |

7 |

8 |

9 |

10 |

13 |

16 |

17 |

| 50HB-25 |

50 |

40 |

H |

32 |

30 |

27 |

25 |

24 |

22 |

19 |

3.5 |

3 |

2900 |

380 |

| Q |

5 |

12 |

19 |

23 |

24 |

26 |

28 |

| 50HB-28 |

50 |

32 |

H |

34 |

32 |

30 |

28 |

25 |

22 |

19 |

3.5 |

2.2 |

2800 |

380 |

| Q |

4 |

8 |

10 |

13 |

15 |

17 |

9 |

| 50HB-32 |

50 |

32 |

H |

37 |

36 |

34 |

32 |

29 |

26 |

23 |

3.5 |

3 |

2900 |

380 |

| Q |

6 |

9 |

13 |

15 |

18 |

21 |

24 |

| 50HB-38 |

50 |

32 |

H |

44 |

42 |

40 |

38 |

35 |

32 |

29 |

3.5 |

4 |

2900 |

380 |

| Q |

9 |

12 |

14 |

16 |

19 |

22 |

24 |

| 65HB-28 |

65 |

50 |

H |

32 |

30 |

28 |

25 |

23 |

21 |

18 |

3.5 |

4 |

2900 |

380 |

| Q |

14 |

20 |

25 |

29 |

32 |

34 |

36 |

| 65HB-32 |

65 |

50 |

H |

36 |

34 |

32 |

29 |

26 |

23 |

20 |

3.5 |

5.5 |

2900 |

380 |

| Q |

14 |

20 |

25 |

30 |

35 |

38 |

40 |

| 65HB-40 |

65 |

40 |

H |

46 |

44 |

42 |

40 |

38 |

35 |

32 |

3.5 |

5.5 |

2900 |

380 |

| Q |

16 |

19 |

22 |

25 |

27 |

30 |

32 |

| 65HB-50 |

65 |

40 |

H |

57 |

55 |

53 |

50 |

47 |

44 |

40 |

3.5 |

7.5 |

2900 |

380 |

| Q |

12 |

18 |

21 |

25 |

28 |

31 |

33 |

| 80HB-13 |

80 |

65 |

H |

16 |

15 |

14 |

13 |

12 |

11 |

10 |

3.5 |

2.2 |

2800 |

380 |

| Q |

25 |

30 |

35 |

37 |

41 |

43 |

46 |

| 80HB-22 |

80 |

50 |

H |

30 |

28 |

25 |

22 |

19 |

16 |

14 |

3.5 |

5.5 |

2900 |

380 |

| Q |

23 |

34 |

39 |

45 |

50 |

55 |

60 |

| 80HB-28 |

80 |

50 |

H |

36 |

34 |

32 |

28 |

25 |

22 |

19 |

3.5 |

7.5 |

2900 |

380 |

| Q |

22 |

31 |

37 |

44 |

49 |

55 |

59 |

| 80HB-30 |

80 |

50 |

H |

36 |

34 |

32 |

30 |

27 |

24 |

21 |

3.5 |

7.5 |

2900 |

380 |

| Q |

32 |

38 |

43 |

47 |

52 |

58 |

62 |

| 80HB-32 |

80 |

50 |

H |

38 |

36 |

34 |

32 |

30 |

28 |

26 |

3.5 |

11 |

2900 |

380 |

| Q |

16 |

30 |

40 |

50 |

56 |

62 |

68 |

| 100HB-13 |

100 |

80 |

H |

18 |

17 |

15 |

13 |

12 |

11 |

10 |

3.5 |

5.5 |

2900 |

380 |

| Q |

50 |

64 |

75 |

84 |

89 |

94 |

98 |

| 100HB-20 |

100 |

80 |

H |

23 |

22 |

21 |

20 |

18 |

16 |

14 |

3.5 |

7.5 |

2900 |

380 |

| Q |

69 |

77 |

83 |

88 |

96 |

105 |

109 |